The demand for lithium batteries keeps increasing as the new energy industry develops at an unprecedented pace in mobile phones, electric vehicles, electric tools, etc. In order to ensure product safety, the production and traceability of lithium batteries become vital factors worth our attention.

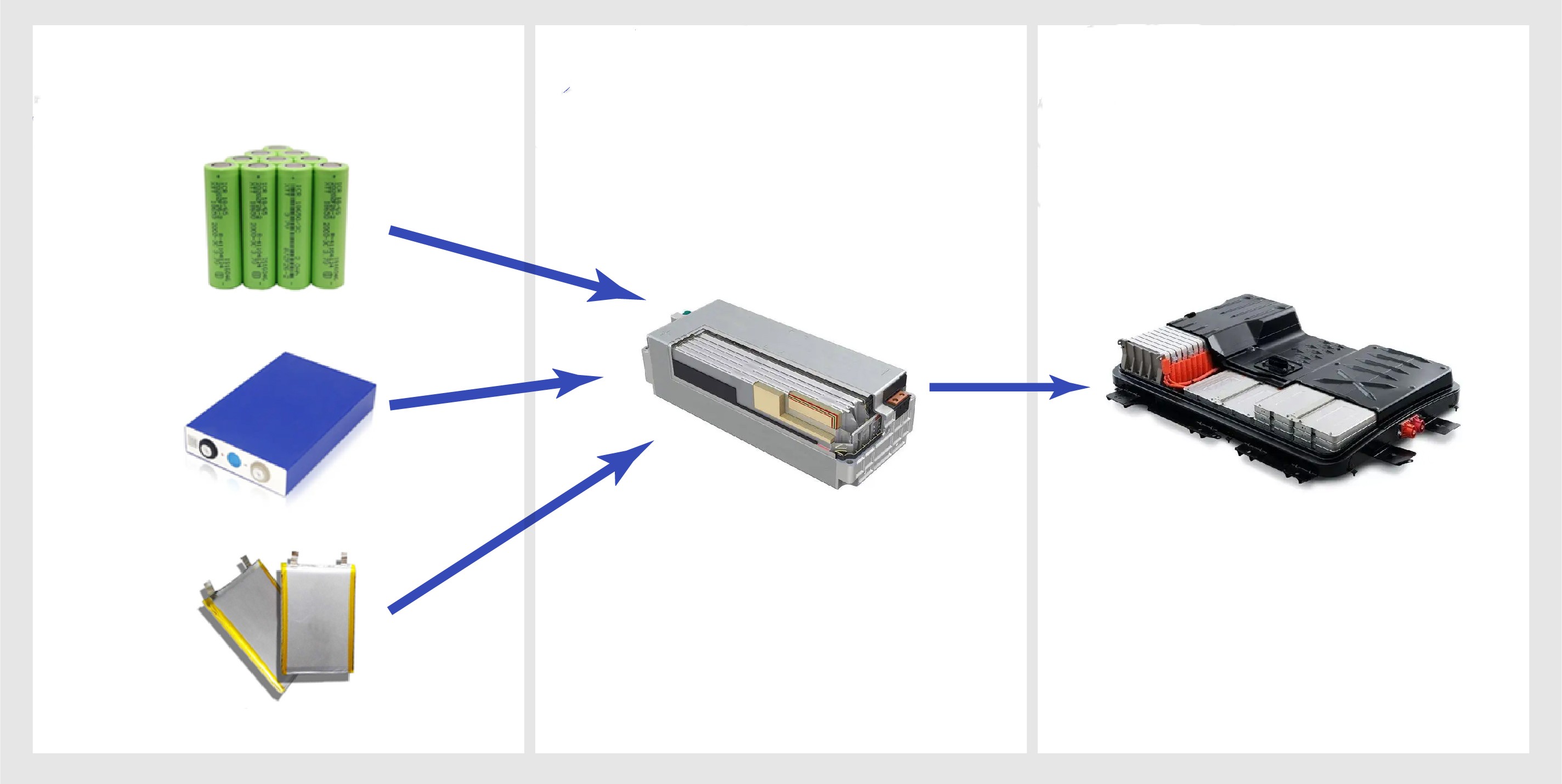

A lithium battery pack is composed of multiple battery modules, and each module is composed of multiple cells.

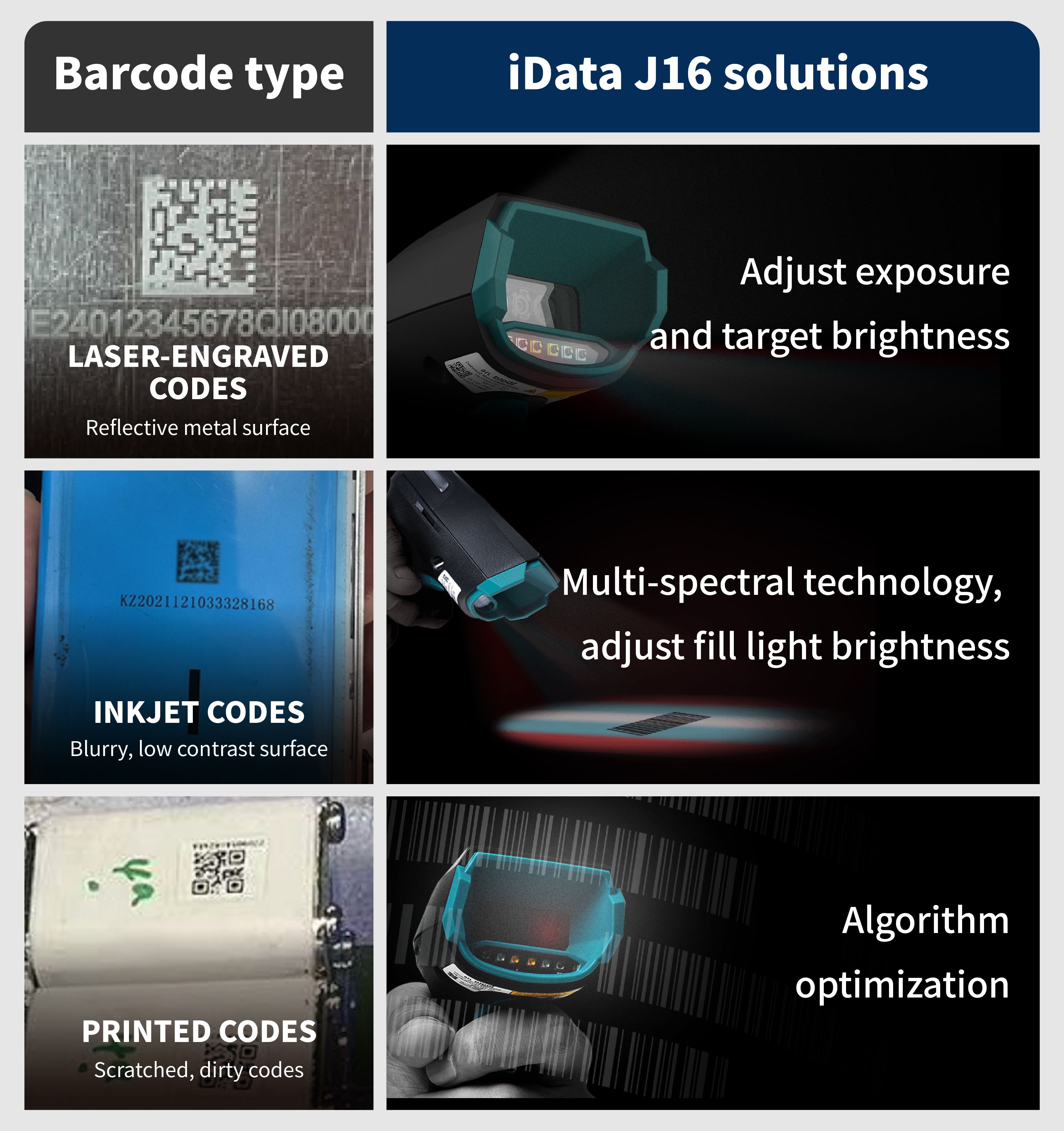

From the production of battery cells to a complete lithium battery, every section needs to be traced. However, we have different types of codes in different sections. They are laser-engraved codes, inkjet codes, and printed codes, etc.

The laser-engraved codes are quite reflective, while the inkjet codes tend to be blurry and have low contrast. A higher standard data collection equipment is required to deal with these types of codes in this industry.

We have upgrade our J16 scanner by strengthening targeted specifications to cope with the current situation, including algorithm optimization, adjustment of exposure and target brightness, and adjustment of fill light brightness. Now iData J16 is fully competent to deal with the difficult-to-read codes in this field.

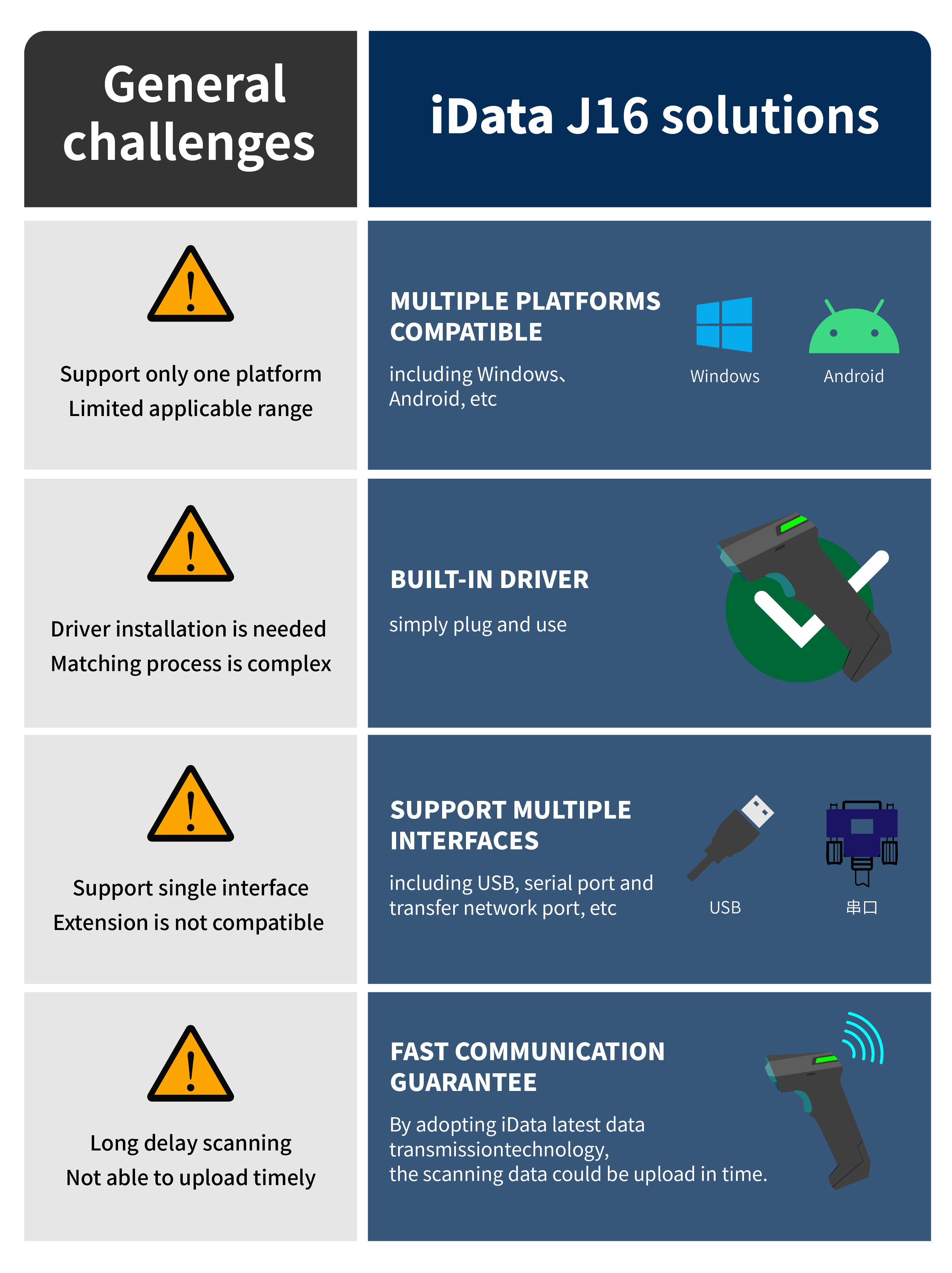

In order to trace the production line, from battery assembly, warehousing to distribution, multiple sections need to be recorded by scanners. The scanners are required to meet the traceability needs in different areas, and have high compatibility for different tasks.

iData J16 scanners have been applied to many Chinese mainstream lithium battery manufacturers and new-energy vehicle manufacturers for production and warehouse traceability management. With the help of J16, many enterprises have benefited from the improvement of lithium batteries' traceability, and the costs of operation and maintenance have been reduced accordingly.

Should you need more details about the application in new-energy industry, or a trial request of iData J16, do not hesitate to reach out to us.

About iData