When it comes to the intelligent manufacturing, digital management solutions are being accepted by more and more manufacturers, and the traceability of electronic products has become more and more important. Adopting barcodes to realize product traceability can not only manage the production process effectively , but also improve the yield rate, so as to create high-quality products.

Recently, iData has reached a cooperation with an electronic component manufacturer to help customers improve the accuracy of barcode scanning and information recording efficiency. iData will share with you the application of manufacturing and the improvement of scanner technology.

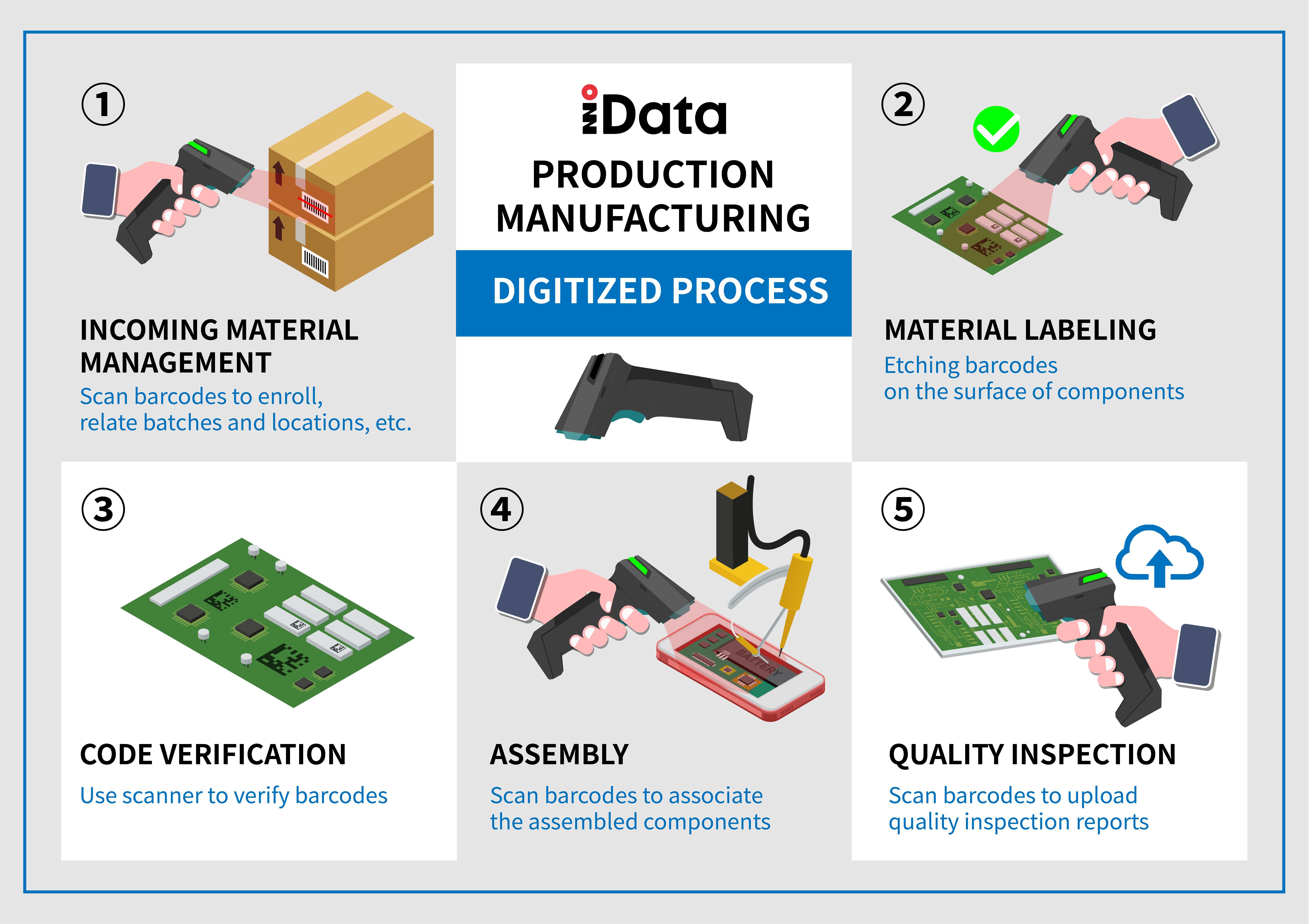

The factory is dedicated to the assembly of mobile phones and computer parts and produces semi-finished mobile phones and computer boards. The production is divided into several sections, they are incoming material management, material labeling, code verification, assembly, quality inspection, etc.

By using the digital management solution, the factory can trace the source of each product, improving the efficiency and accuracy of quality inspection, maintenance management, etc. It can also manage and assess the performance of assembly employees and implement responsibility-to-person management.

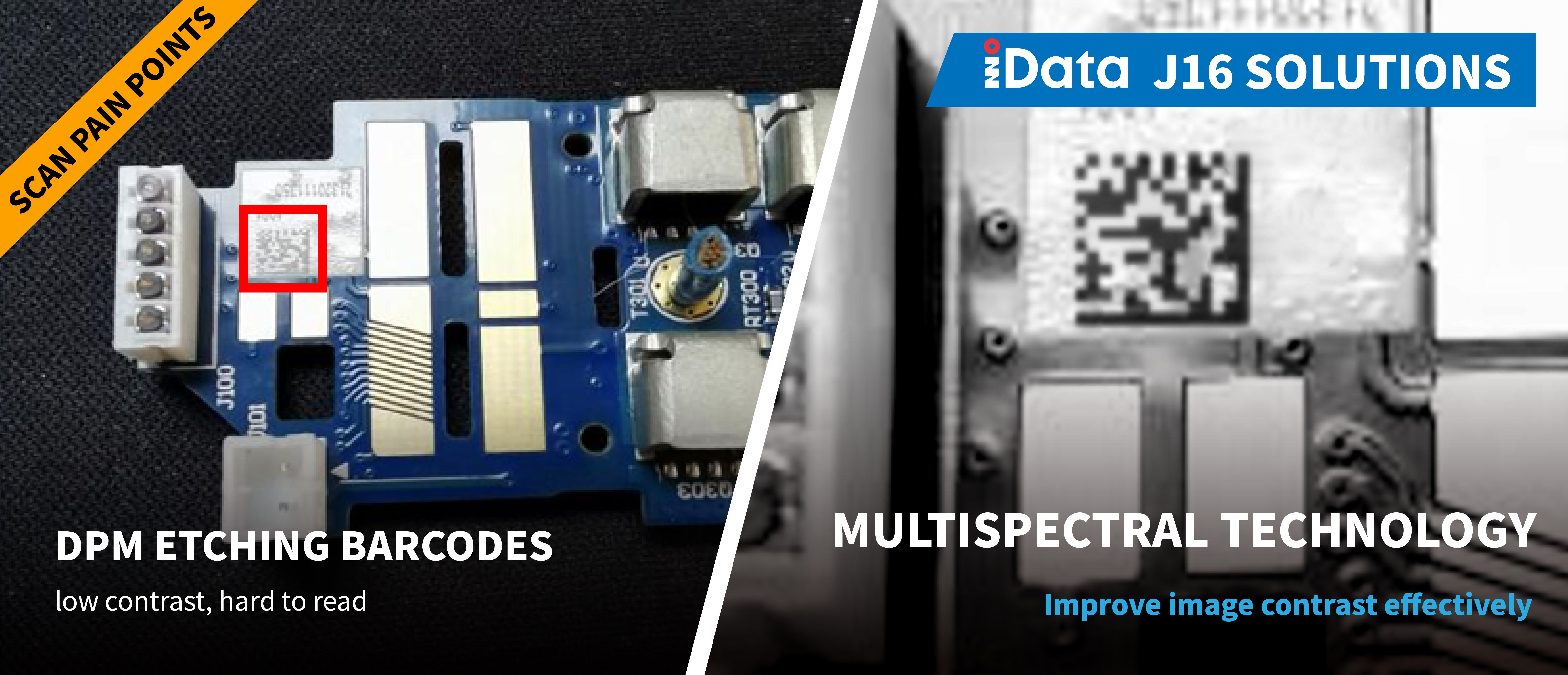

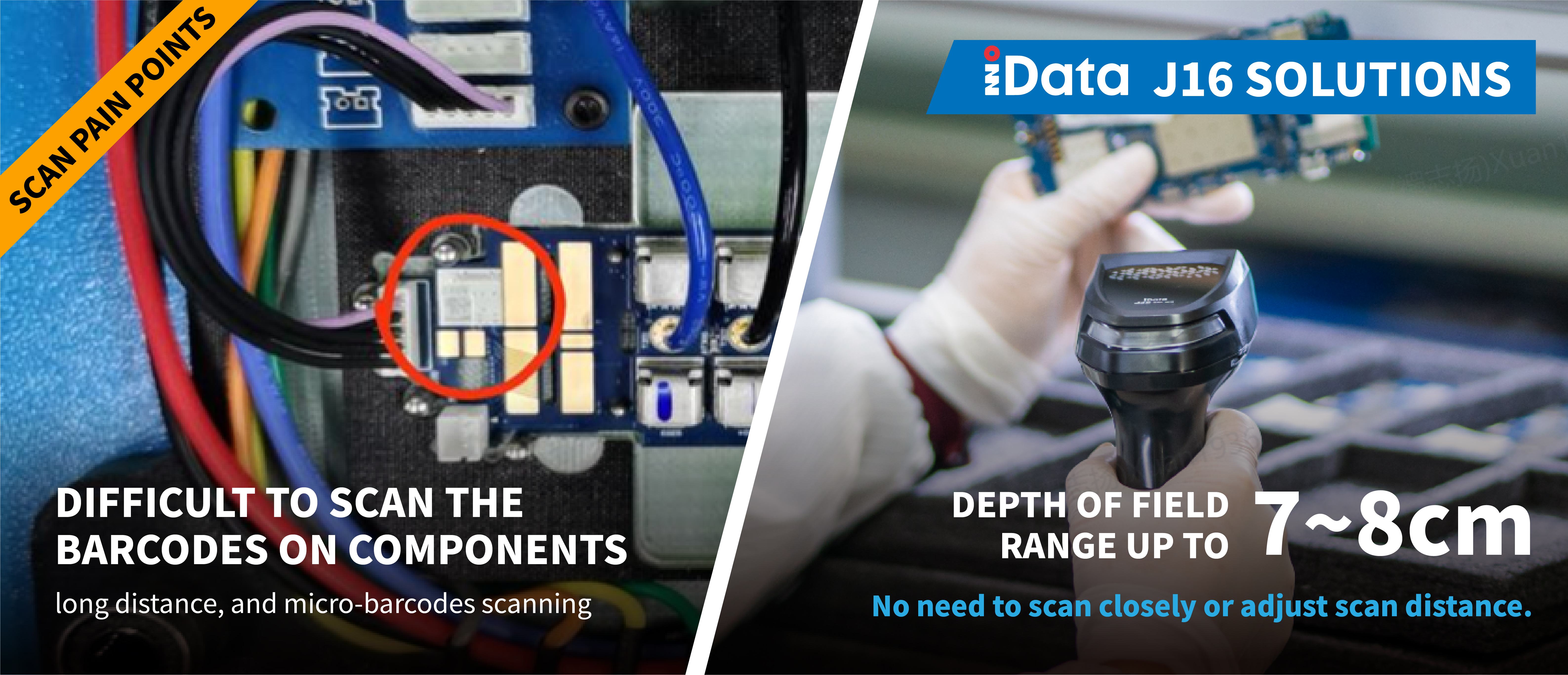

As we studied the case of our client who adopt scanners in the process of code verification and assembly, we discovered a few obstacles, for example the DPM barcode has low contrast, the barcodes are small, and there are many cables after the assembly, which makes the codes more difficult to scan.

In order to solve the problems in this situation, iData scanner has upgraded 3 advanced technologies which are the keys to the efficient scanning.

Now many electronic manufacturing factories in China have adopted iData J16 for production traceability management, and the use of iData's latest scanning technology has improved the digital management capabilities of enterprises significantly.

About iData