The Automobile industry is experiencing a huge price drop since March 2023. The competition becomes more and more fierce. In order to help enterprises gain competitive edges, precise on-demand production and distribution are being introduced to reduce the operating costs of the auto industry.

Recently, iData has cooperated with a well-known vehicle manufacturer, and with the help of RFID digital technology, it has helped the factory upgrade the digital management system for the inbound and outbound storage of finished cars, which has improved the turnover efficiency of the finished products.

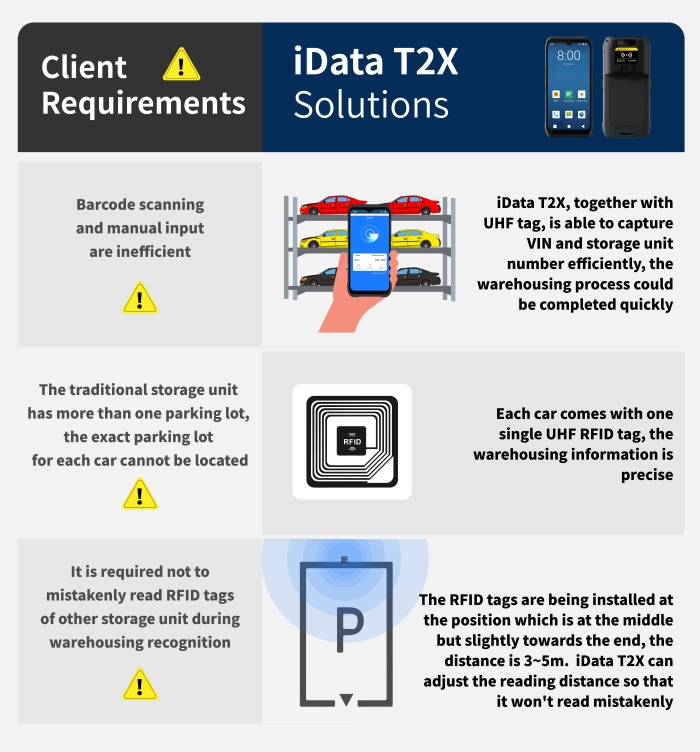

After the production of the automobile is finished, the products need to be moved from the production line and transferred to the parking lot for temporary storage. They usually scan barcodes or input information manually to complete the warehousing process, which is time-consuming. While using iData T2X RFID handheld terminal with UHF RFID reading module can efficiently identify the Vehicle Identify Number (VIN) RFID tag and the RFID tag of the storage unit, the warehousing process could be completed all at once.

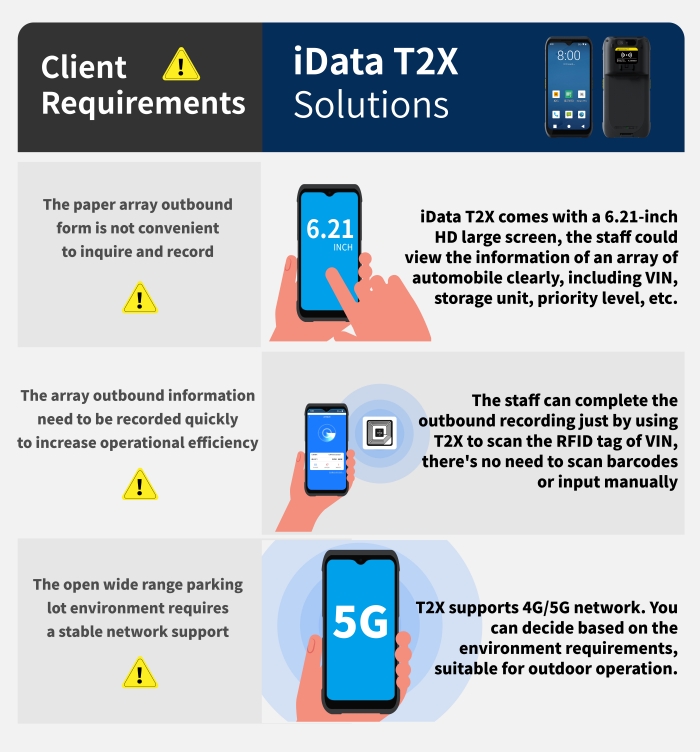

When the automobiles in the warehouse are ready to be shipped to dealers or 4S stores in various places, the staff will execute the outbound process of an array of automobiles based on the“first-in, first-out” principle, then make them ready for truck transportation. The visualized array management can directly send the work order to the employee's T2X terminal, improving work efficiency and accuracy.

Currently, the application of iData T2X RFID handheld terminal has improved the efficiency of inbound and outbound management of the finished automobiles, and gradually replace the traditional paper and barcode methods, cutting operational costs of warehouse dramatically.

If you want to learn more about the applications in the automobile manufacturing industry, or try out iData T2X, do not hesitate to contact us.