As the competition of apparel industry become fierce these years, more and more clothing production companies have introduced digitized clothing management system to optimize the production process, the productivity and competitiveness of the company could be improved accordingly.

iData started cooperation with one well-known ERP software service provider of apparel industry recently. With the unmatched edges of iData T2X RFID handheld terminal, iData is able to provide several apparel production companies with a more flexible and efficient digitized management solution.

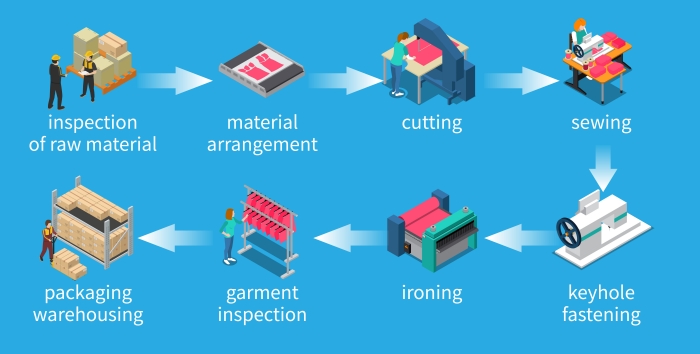

There are many processes in clothing production, such as inspection of raw material, material arrangement, cutting, sewing, keyhole fastening, ironing, garment inspection, packaging and warehousing, etc.

During the production process, the production line staff salaries are based on piecework rate, while the management staff need to take control of the real-time production situation, adjust or optimize production process if necessary. In this way, they could achieve the production goal in time.

Now with the help of iData T2X RFID handheld terminal equipped with the LF RFID reading module, it can meet the needs of staff piecework recording and production line management, taking the production efficiency into next level.

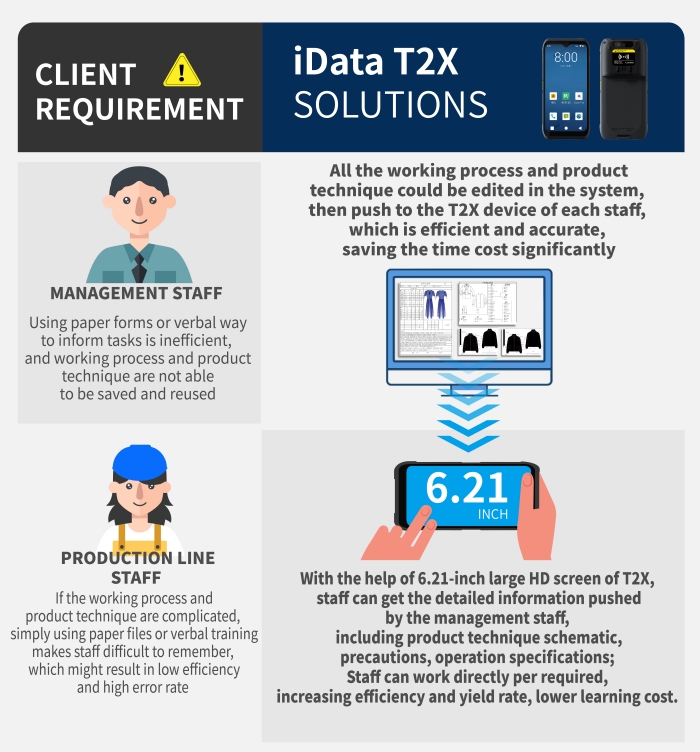

The production process and product technique management are usually delivered by managers verbally or in paper files, which is inefficient and has a high error rate, affecting the production schedule and yield rate. With the visualized product technique push carried out by T2X, all these problems could be solved.

The digitized management and visualized product technique of iData T2X have gradually replaced the traditional management mode, and the production line efficiency and yield have been greatly improved.

To learn more about the apparel industry or try iData T2X, do not hesitate to get in touch with iData.